Copper is a red-orange, soft and ductile metal that is renowned for its corrosion resistance and malleability. Used as part of The SIFCO Process® , copper plating helps reduce lead times and produces high-quality components to exacting specifications. We’ve answered the most frequently answered questions about copper electroplating in this blog.

What is selective copper electroplating?

Selective copper electroplating is a method of brush plating that doesn’t require an immersion tank. Using a specialized plating kit, copper deposits are applied to localized areas of a component using an anode and a power pack.

How do you electroplate with copper?

In the simplest of terms, when a component is selectively plated with copper, the metal substrate receives a negative charge from the power pack, while the anode is positively charged. Once the base material is properly prepared for a metal finish, the technician then dips or flows the copper electrolyte to soak the anode. The copper soaked anode is then placed on the surface to be plated. The current makes the copper ions adhere to the component’s surface, which creates a thin copper coating.

What is copper plating used for?

There are many advantages of copper plating, and can be used across many applications and industries. Here are just a few uses of copper:

- Copper can improve the conductivity.

- Due to its malleability, it is great for components that bend.

- Copper offers excellent protection against corrosion.

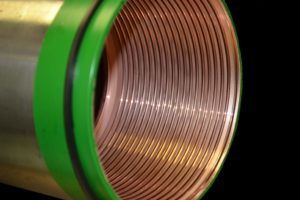

- Copper prevents galling on threaded connections.

- Copper can be built up in high thicknesses to repair mechanically damaged surfaces.

What specifications apply to selective copper plated components?

SIFCO ASC’s Copper Select Plating Program is VAM and Tenaris qualified. And we manufacture various copper solutions which meet AMS 2451/6, Mil-Std 2197A (SH), and Mil-Std 865.

Which industries use copper plating?

Because of copper’s thermal properties, corrosion resistance and conductivity, a wide variety of industries use copper plating for their heating, electrical and industrial applications. Copper is widely used in the following industries:

- Due to its anti-galling properties copper plating is widely used in the Oil & Gas and subsea mining industries for threaded pipe connections.

- HVAC industry commonly uses copper plating for heat exchangers, boilers, steam condensers and more.

- Copper is widely used in remanufacturing as it helps build up worn out and corroded parts.

- Due to its natural antifouling properties, copper is used in the marine industry because it saves cleaning and decreases the chance of mechanical breakdown.

Copper electroplating with SIFCO ASC

SIFCO ASC has been providing plating services across a wide range of industries for over 50 years. We are the largest supplier of contract selective electroplating and anodizing services in the world. To find out how we can help you with your copper plating needs, get in touch.

Chinese (Simplified)

Chinese (Simplified)  English

English  French

French  German

German  Spanish

Spanish  Swedish

Swedish