Between credit and debit card issuers to the automotive and technology sectors, many industries are being affected by a global semiconductor shortage. This was partially down to a demand spike in the pandemic as well as supply-chain issues.

Between credit and debit card issuers to the automotive and technology sectors, many industries are being affected by a global semiconductor shortage. This was partially down to a demand spike in the pandemic as well as supply-chain issues.

According to the American Machinist “The pandemic highlighted how semiconductor suppliers were ill-prepared for shocks, as some manufacturers faced thousands of product shortages per day”.

With chip factories being expensive to build and labor-extensive to operate, solving these challenges won’t be an easy task. In fact, it takes an estimated minimum of $10 billion to build a new chip manufacturing plant. And, that doesn’t include the workforce needed to operate it. Intel, for example, plans to build two semiconductor factories in Ohio, but these will need approximately 7,000 workers. This is particularly difficult with an ongoing workforce and talent shortage.

But this is where new technologies, processes, and investments can help companies work towards a solution.

Investments to tackle semiconductor shortages

The challenge facing semiconductor manufacturing has led to the US Government’s CHIPS and Science Act to boost American semiconductor research, development, and production.

The challenge facing semiconductor manufacturing has led to the US Government’s CHIPS and Science Act to boost American semiconductor research, development, and production.

According to a recent statement from the White House: “America invented the semiconductor, but today produces about 10% of the world’s supply – and none of the most advanced chips. Instead, we rely on East Asia for 75 percent of global production. The CHIPS and Science Act will unlock hundreds of billions more in private sector semiconductor investment across the country, including production essential to national defense and critical sectors.”

Following this act passing, companies across the semiconductor manufacturing sector announced nearly $50 billion in additional investments.

Going beyond shortages: four challenges facing semiconductor manufacturing

As well as the shortages, the semiconductor sector still faces several challenges that affect the reliability and durability of semiconductors. Here are the four top challenges semiconductor manufacturers need to overcome…

- Corrosion: This can occur because of exposure to moisture and other environmental factors. Corrosion can cause many problems including reduced performance, device failure and increased maintenance costs.

- Miniaturizations: As the demand for smaller and more complex devices increases, the size of semiconductors continues to shrink. This makes it more difficult to protect them from environmental factors like moisture, which can cause corrosion and other damage.

- Material compatibility: Semiconductors are made from a variety of materials, each with unique properties and characteristics. The challenge is to find a coating material that is compatible with the semiconductor material and provides adequate protection against corrosion.

- Cost: The semiconductor industry is highly competitive, and cost is always a concern. That’s why manufacturers must seek cost-effective solutions for corrosion protection without sacrificing quality.

Selective plating: an effective solution for corrosion protection

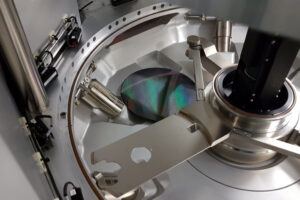

Selective plating is an electroplating technique that is used to deposit a thin layer of metal on a specific area of a substrate to provide corrosion protection for semiconductor components. One of the benefits of selective plating is that it can be used only on the areas that need protection, helping to reduce material usage and minimize the impact on the device’s electrical properties.

It can also be used with a variety of metal coating materials, including gold, silver, and nickel. This makes it possible to choose a coating material that is compatible with the component’s base material and provides adequate protection against corrosion.

Plus, selective plating is a cost-effective solution for corrosion protection. This is because the technique is relatively simple and can be performed on-site with standard electroplating equipment. This makes it possible to integrate selective plating into existing production processes without significant additional investment.

How SIFCO ASC can help the semiconductor industry

At SIFCO ASC, we have the knowledge and expertise to help manufacturers of aluminum chemical vapor deposition (CVD) tooling which requires Selective Nickel Plating (SNP).

This tooling gets worn out with use and is replaced by the semiconductor manufacturers. Research into the possible recoating of tooling is being investigated as an option to prolong the life of the equipment and avoid any unnecessary repair costs or downtime.

When it comes to the steel enclosures used in CVD processing equipment, manufacturers require selective plating of zinc with the main purpose of create ground area for electrical panel cabinets.

By working with SIFCO you can get help with:

- Concept and design: Our R&D and Engineering expertise can help you find the right solution for your application.

- Production: In this phase, our technical support team and contract service technicians can provide the skill and labor to carry out the most demanding applications. We also have certified trainers that can offer a hands-on experience for our customers so that they can plate their equipment on site without disruption to their production. Technicians will learn how to troubleshoot plating applications and accurately plate numerous deposits.

- Procurement and logistics: To make sure your solutions, supplies and equipment are readily available when and where they are needed, our team is on hand throughout the process.

For more information about how the SIFCO Process® and selective plating can help your semiconductor business, contact our team today.

Chinese (Simplified)

Chinese (Simplified)  English (UK)

English (UK)  French

French  German

German  Spanish

Spanish