On July 26th, 40km away from the Eiffel Tower and the 2024 Olympics opening ceremony, SIFCO ASC France demonstrated its know-how in its own way.

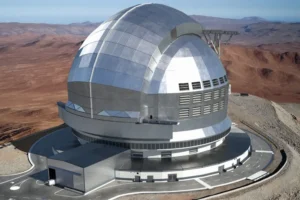

Safran Reosc, a world leader in high performance optical systems, manufactures all the mirrors of the future Extremely Large Telescope (ELT). Led by the international consortium ESO, this €1,5 billion project aims at assembling and commissioning the largest telescope on earth in the Atacama Desert in Chile by 2028. In short, the ELT is a revolutionary ground-based telescope that will have a 39-metre main mirror and will be the largest visible and infrared light telescope in the world: the world’s biggest eye on the sky. In addition to this unparalleled size, the ELT will be equipped with a lineup of cutting-edge instruments, designed to cover a wide range of scientific possibilities.

Safran Reosc, a world leader in high performance optical systems, manufactures all the mirrors of the future Extremely Large Telescope (ELT). Led by the international consortium ESO, this €1,5 billion project aims at assembling and commissioning the largest telescope on earth in the Atacama Desert in Chile by 2028. In short, the ELT is a revolutionary ground-based telescope that will have a 39-metre main mirror and will be the largest visible and infrared light telescope in the world: the world’s biggest eye on the sky. In addition to this unparalleled size, the ELT will be equipped with a lineup of cutting-edge instruments, designed to cover a wide range of scientific possibilities.

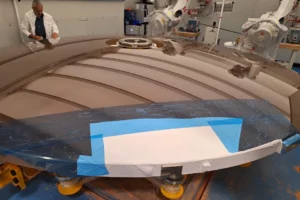

While the main mirror has a 39-meter diameter, Safran Reosc reached out to SIFCO ASC France to treat parts for the secondary 4-meter diameter mirror. Several lateral supports of the mirror needed to be nickel-plated. SIFCO ASC France leveraged its portable Selective Electroplating technology to perform the treatment in-situ without disassembling the supports. A layer of 50 microns of nickel was plated using the SIFCO Process to help prevent corrosion.

This intervention is a perfect example of SIFCO ASC’s globally recognized technical expertise. The SIFCO Process enable technicians to perform the plating locally, on the exact area requiring the repair, without disassembling the part. Most of the plating in the world is done in baths, where the parts are fully immersed in large tanks. Here this would have required Safran to dismantle the Lateral Supports which would have been very costly and would have delayed the project. Our Selective Electroplating technology offers the opportunity to plate without the use of an immersion tank.

This intervention is a perfect example of SIFCO ASC’s globally recognized technical expertise. The SIFCO Process enable technicians to perform the plating locally, on the exact area requiring the repair, without disassembling the part. Most of the plating in the world is done in baths, where the parts are fully immersed in large tanks. Here this would have required Safran to dismantle the Lateral Supports which would have been very costly and would have delayed the project. Our Selective Electroplating technology offers the opportunity to plate without the use of an immersion tank.

To learn more about selective plating, click here.

English (UK)

English (UK)  French

French  German

German  Spanish

Spanish  Swedish

Swedish